Gray Water Treatment Systems

Off Grid Gray Water Treatment Systems are low-cost technologies that enable rural communities living in water scarce areas to reuse household waste water for agricultural purposes, thereby conserving limited water resources.

What is Off Grid, What is Gray Water, What is Treatment + Other Key Concepts? If you are not familiar with these concepts, then we recommend you take a moment to familiarize yourself with them before you head into the discussion of the specific technologies. If you are comfortable with this vocabulary, then you can skip the glossary and go directly to the system descriptions.

| Gray Water | All wastewater generated by households or office buildings from sources without fecal contamination. Note: There are several definitions of gray water in the technical literature. The main distinction between them concerns kitchen wastewater (whether it should be included or not). For the purpose of this project, it is. | ||||

| Off Grid | A household or community not connected to a centralized electrical infrastructure. | ||||

| Treatment | Any process that reduces the water’s impurities, i.e. water purification, making it suitable for (in our case) agricultural irrigation. | ||||

| Treatment– Aerobic | Biodegradation of pollutants by oxygen consuming bacteria. | ||||

| Treatment– Anaerobic | Biodegradation of pollutants by bacteria that break down material in the absence of oxygen. These bacteria use alternative oxygen sources such as sulfate and nitrate. | ||||

| Treatment– Passive Biological | Biodegradation of pollutants in which bacteria is the biodegrading agent. | ||||

Three Models of Off Grid Gray Water Treatment Systems

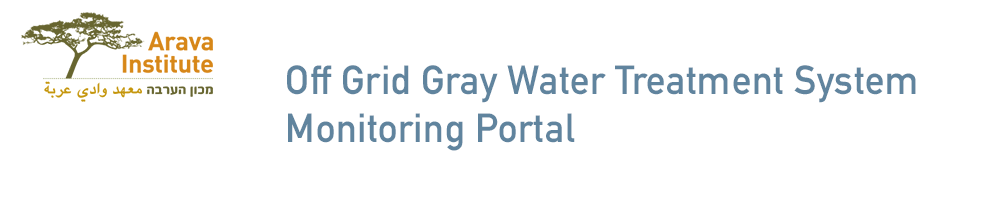

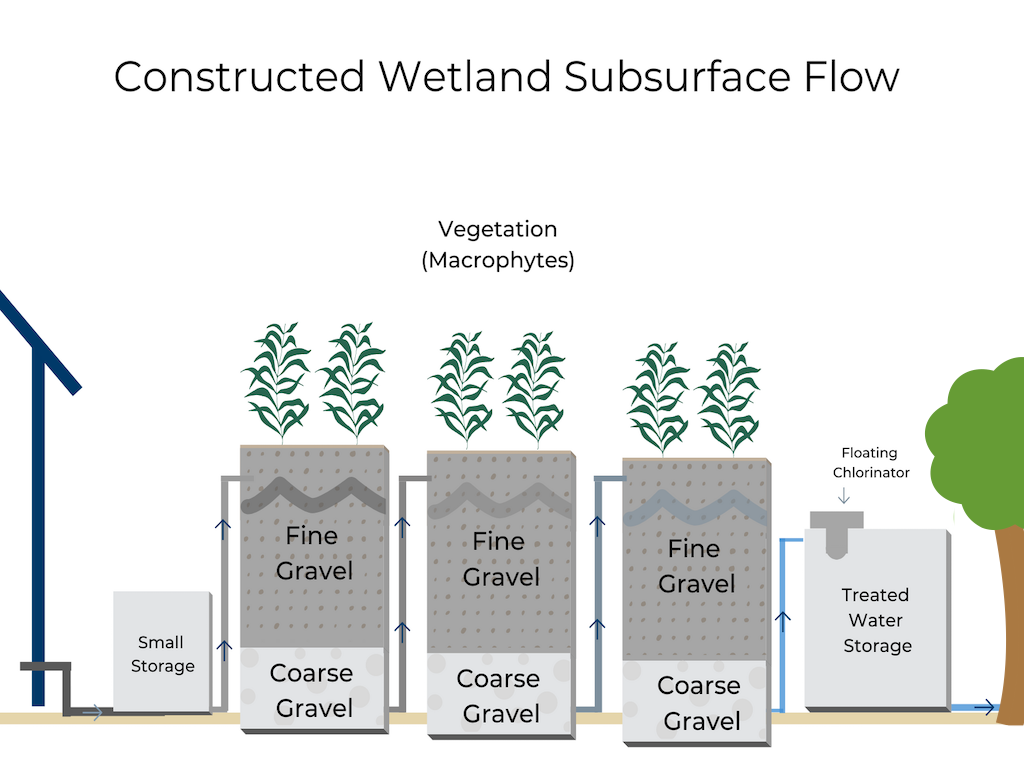

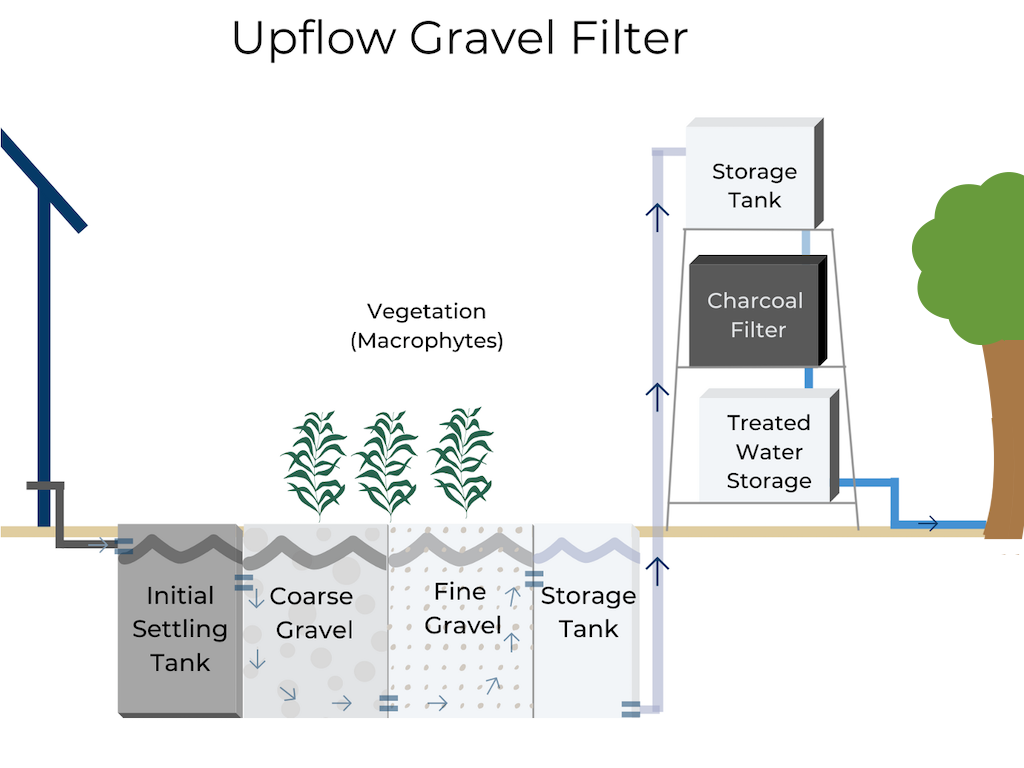

Subsurface Flow and Upflow Gravel systems are considered types of Constructed Wetlands. The Vertical Greenwall is an instance of Trickling Wastewater Treatment.

— Click on image to see full-size schematic —

Subsurface Flow

Upflow Gravel

Vertical Greenwall

All three technologies are used to treat and reuse gray water and are suitable for off-grid application due to their low-energy requirements. Each has its advantages and disadvantages. The preferred system for a given locality depends on socioeconomic factors, the physical and climatic environment, as well as placement proximity to household dwellings.

Constructed Wetlands are low-cost, low-maintenance wastewater treatment systems designed to mimic water cleansing processes found in natural wetlands.

Both Subsurface Flow and Upflow Gravel systems use a gravel substrate to purify gray water by passive biological treatment. These treatment methods remove pollutants from the gray water with minimal electrical energy requirements, which can be provided by small solar photovoltaic panels, thereby making them suitable for off-grid situations. This makes them ideal for economically distressed and/or remote locations.

In both systems, gray water enters the top of the basin (container), is drawn down through the gravel media by gravity, and is then collected by a drainage pipe. A biofilm of microorganisms forms on the water saturated gravel substrate to capture, biodegrade, and remove pollutants from the water as it passes through the system (passive biological treatment). The resulting water can be further disinfected, often by chlorination, or used directly for agricultural irrigation.

Components of Constructed Wetlands As seen in the schematics, Constructed Wetlands consist of five major components: 1) basin, 2) substrate, 3) vegetation (macrophyte plants), 4) liner, and 5) piping (for water entry and drainage).

Gravel is used as the substrate for both types of Constructed Wetland systems. The number of basins (containers) depends on the volume of gray water being treated. Water collects in an outflow collection tank, where it can be used for irrigation via a pump and hose.

Differences between Subsurface Flow and Upflow The primary difference between the Subsurface Flow and Upflow Gravel systems is that the Subsurface Flow system consists of a single aerobic phase while the Upflow Gravel system consists of an anaerobic phase followed by an aerobic phase. Additionally, for the Upflow Gravel system, hydrostatic (water at rest) pressure helps to move the water from the anaerobic compartment to the top of the aerobic compartment. However, a small pump, powered by a solar panel, is also required.

The Subsurface Flow system also uses a solar panel to provide electricity to move water into its initial compartment. The rest of the process is gravity driven.

The Function of Vegetation Vegetation is an important component of a constructed wetlands treatment process. Plant roots facilitate nutrient uptake, provide a growth media for pollutant-degrading bacteria, and increase oxygen availability. The constructed wetlands of this project use macrophytic plants, which are plants that grow in or around water. These plants are well suited for this purpose and are commonly used in constructed wetlands.

A Trickling Wastewater Treatment system works by dripping wastewater down a fixed substrate. A biofilm of microorganisms forms on the substrate, facilitating passive biological treatment of the wastewater it comes in contact with.

The Vertical Greenwall is an instance of a Trickling Wastewater Treatment system. The Vertical Greenwall uses a plastic curtain hung as a vertically fixed substrate. Gray water enters the top of the unit and is dripped down the curtain. The water is treated upon contact with the biofilm that forms on the curtain. The water cycles through the system multiple times before being released from the system and used for agricultural irrigation. The Vertical Greenwall uses solar energy to pump the water up to the top of the basin to cycle the water through the system.

Major Comparative Considerations

| Considerations | Subsurface Flow | Upflow Gravel | Vertical Greenwall |

|---|---|---|---|

| Space Requirements | largest | mid | smallest |

| Odor | moderate | moderate | minimal |

| Operation & Maintenance Effort | mid | most | least |

| Installation Costs | low | moderate | high |

| Quality of Water Produced | moderate | moderate | high |

Approximate System Costs

| Gray Water Treatment Technology | Approximate Costs (USD) |

|---|---|

| Upflow Gravel | $10,000 |

| Subsurface Flow | $15,000 |

| Vertical Greenwall (gray water only) | $20,000 |

| Vertical Greenwall (gray water & black water) | $20,000 |

Recommended System Maintenance Routines

All active agricultural machinery and production systems require routine maintenance to assure they continue to operate

efficiently, continually and safely. The gray water treatment systems discussed here are, of course, no exception.

This section concisely

outlines the basic (required) maintenance routines separately for each type of gray water treatment system as well as for the Ayyeka data collection

sensors embedded in them. References are cited for more extensive discussion of the maintenance requirements.

Please Note While performing these maintenance tasks, be sure to minimize exposure to wastewater by wearing personal protective gear and waterproof gloves. After completing the maintenance, thoroughly wash hands and/or shower to ensure safety.

The Subsurface Gravel Wetland system does require maintenance to ensure effective wastewater treatment. The majority of the maintenance requires casual observations to identify potential problems and to address them.

| System Element | Maintenance Task | Task Frequency |

|---|---|---|

| Inlets, Outlets | Check that inlets and outlets to each submerged gravel wetland cell are open and not clogged. | Monthly |

| Gravel Beds | Check water level, which should be within 1-3 inches of the gravel surface. Add water if needed. If going on a long vacation, or if there will have extended time without water pumping through the system, ensure that water will be added so as to not damage plants. | Monthly |

| Gravel Beds | Check for standing water or other evidence of clogging. If so, check inlets and outlets for clogs. If no clogs or problems are detected, there might be too much wastewater entering the system, so limit how much is added while the excess cycles through. | Every 6 months |

| Gravel Beds | Check for sediment buildup in gravel beds. If flow is obstructed through the wetland, remove gravel and sediment from the cell, replace with clean gravel, and replant vegetation. | Annually |

| Vegetation | Check that plants are healthy. Remove dead plant material, water plants as necessary, and revegetate poorly established plants as necessary. | Monthly |

| Initial Storage Tank | Check the level of accumulated solids within the initial storage tank. If they exceed 1/3 of the tank, a professional septic tank pumper should clean the tank. | Every 3-5 years |

| Note Use the browser back button (<-) to return to the Portal from each of the sources. |

The Upflow Gravel Wetland system does require maintenance to ensure effective wastewater treatment. The majority of the maintenance requires casual observations to identify potential problems and to address them.

| System Element | Maintenance Task | Task Frequency |

|---|---|---|

| Water Levels | Visually inspect the beds to see that water is flowing all the way through the system. If not, check inlets and outlets to ensure nothing is clogged. | Weekly |

| Gravel Beds | Check water level, which should be within 1-3 inches of the gravel surface.

Add water if needed. Turn off the system by interrupting the inflow. Using a shovel, manually stir the

surface layer of the gravel. Fill the unit 20 cm above the gravel bed by opening the inlet valve and letting it drain through. If flow is obstructed, check the inlets and outlets and stir the gravel. If flow is still obstructed, remove gravel and sediment from the bed and replace with clean gravel. Be sure to turn on the inflow afterward. |

Weekly |

| Initial Storage Tank | Check the level of accumulated solids within the initial storage tank. If they exceed 1/3 of the tank, a professional septic tank pumper should clean the tank. | Every 3-5 years |

| Sources | — Upflow gravel filtration for multiple uses |

| Note Use the browser back button (<-) to return to the Portal from each of the sources. |

The Vertical Greenwall system, capable of processing 25 cubic meters of wastewater daily, requires very little maintenance, as most of its functions are monitored remotely by a water professional, therefore problems will be detected early. The system should still be periodically checked visually to prevent problems from arising.

| System Element | Maintenance Task | Task Frequency |

|---|---|---|

| Inlets, Outlets | Check that inlets and outlets are free of debris and not clogged. | Monthly |

| Initial Storage Tank | Check the level of accumulated solids within the initial storage tank. If they exceed 1/3 of the tank, a professional septic tank pumper should clean the tank. | Every 2 years |

| Sources | — Assa Amir, Bio Resources, Naharia, Israel |

| Note Use the browser back button (<-) to return to the Portal from each of the sources. |

The Ayyeka sensors that monitor the water quality in the systems are important in determining and reporting the efficiency of the wastewater treatment. The sensors must be regularly cleaned to assure accuracy. They also require occasional calibration testing and recalibration when necessary.

| System Element | Maintenance Task | Task Frequency |

|---|---|---|

| EC, pH, DO, Turbidity |

Check cleanliness to ensure no interferences to probe activity. Clear off debris as needed. | Weekly |

| EC & pH | Clean by rinsing with freshwater. If readings have been inconsistent, recalibrate the probe. | Every 3 months |

| DO | Clean by rinsing with freshwater. Test sensor with a sodium sulfate solution (17 mg of sodium sulfite in 125 mL of water). Sulfur water for DO should read near 0 ppm. If not, contact the system manager. | Every 6 months |

| Turbidity | Clean by rinsing with freshwater. Test the sensor with clean water. It should be near 0. If not, contact the system manager. | Every 6 months |

| Sources | — Guidelines and Standard Procedures for Continuous Water-Quality Monitors |

| Note Use the browser back button (<-) to return to the Portal from each of the sources. |

Page last updated: Tue 11 May 2021